What are the key components of an diaper packaging machine?

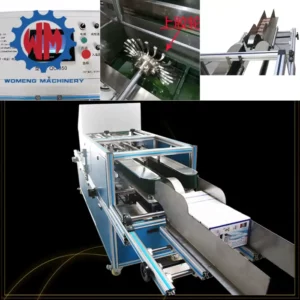

An diaper packaging machine consists of several key components that work together to automate the packaging process efficiently.

Some of the essential components include:

- Feeding Mechanism: This component feeds diapers into the packaging machine, ensuring a consistent flow of products for packaging.

- Packaging Material Handling: Components for handling packaging materials, which may include films, wrappers, or bags used to encase the diapers.

- Sealing and Cutting Mechanism: Machinery for sealing and cutting the packaging materials to create individual packs or bags for diapers.

- Folding or Stacking System: Components that fold or stack diapers neatly before they are packed into the final packaging material.

- Labeling and Printing Units: Equipment for labeling, printing batch numbers, expiry dates, or other essential information on the diaper packaging.

- Conveyors and Transport Systems: Conveyor belts or transport systems that move diapers through different stages of the packaging process.

- Control and Automation Systems: Control panels, sensors, and automation systems that regulate the machine’s operation, ensuring accuracy and consistency in packaging.

- Quality Inspection and Rejection Mechanisms: Inspection units equipped with sensors or cameras to detect defects or irregularities in diapers before packaging. Rejection mechanisms remove faulty products from the line.

- Wrapping or Bundling Equipment: Machinery for bundling multiple packs of diapers together or wrapping them for shipping or retail display.

- Safety Features: Various safety components such as guards, emergency stop buttons, and safety interlocks to ensure operator safety during machine operation.

These components collectively form an integrated system that automates the diaper packaging process, ensuring efficiency, accuracy, and quality in packaging diapers for distribution and retail sale.

Can the machine produce different sizes and styles of diaper packaging machine?

Yes, many diaper packaging machines are designed with the flexibility to produce different sizes and styles of diaper packaging. These machines can be adjusted, diaper packaging machine configured, or equipped with interchangeable parts to accommodate various sizes, styles, or configurations of diaper packaging.

Here’s how they achieve this:

- Adjustable Settings: Machines can be programmed or adjusted to accommodate different packaging sizes, lengths, widths, or styles, allowing for versatility in production.

- Changeover Capabilities: Diaper packaging machines often have quick changeover features that enable rapid transitions between different packaging sizes or styles, minimizing downtime during transitions.

- Customizable Tooling or Components: Some machines offer interchangeable tooling, parts, or components that can be swapped or adjusted to produce different packaging sizes or styles.

- Modular Design: Machines with a modular design allow for easy integration or replacement of modules tailored to specific packaging requirements, supporting flexibility in production.

- Multiple Formats and Configurations: These machines can handle various formats, such as bags, pouches, or boxes, and can adapt to different sealing methods or closure mechanisms as required for diverse packaging styles.

- Programming and Controls: Advanced control systems enable operators to input parameters for different packaging sizes or styles, allowing the machine to adjust settings accordingly.

- Customization Options: Manufacturers often provide customization options when acquiring these machines, allowing clients to specify their requirements for producing different diaper packaging sizes or styles.

By leveraging these features and functionalities, diaper packaging machines offer the adaptability needed to produce diverse packaging sizes, styles, or configurations, enabling manufacturers to cater to varying consumer preferences and market demands.