What are plate and frame filter presses, and how do they work?

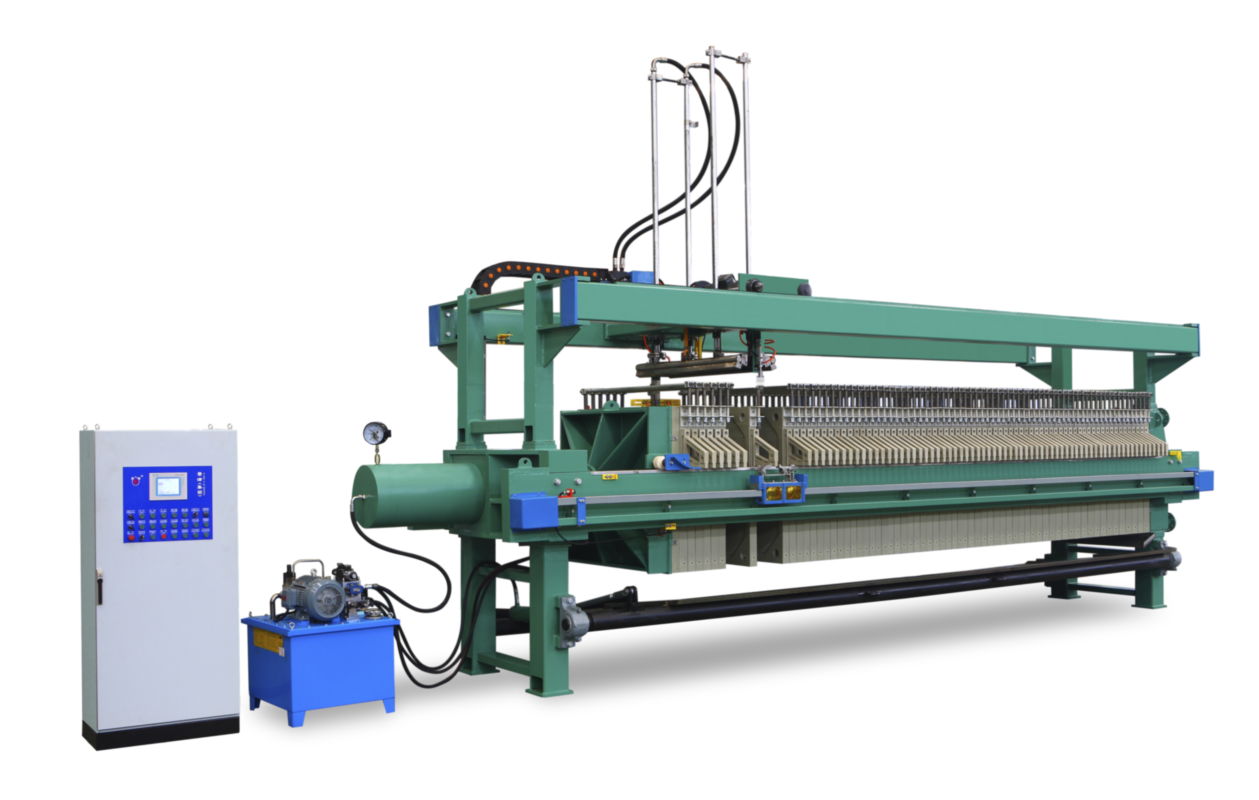

Plate and frame filter presses are a type of industrial filtration equipment used to separate solids from liquids. The filter press consists of a series of alternating plates and frames, which are arranged to form a set of filter chambers. Each chamber is filled with a filter medium, which can be a cloth, paper, or other material. The plates and frames are pressed together under high pressure, which forces the liquid through the filter medium, leaving behind the solids. The separated solids form a cake on the filter medium, which can be easily removed from the press. Plate and frame filter presses are commonly used in a wide range of industries, including food and beverage, pharmaceuticals, chemicals, and mining.

Question 2: What are the benefits of using plate and frame filter presses?

Plate and frame filter presses offer several benefits over other types of filtration equipment. They are highly efficient and can achieve high levels of solid-liquid separation in a single pass. They are also versatile and can be used to filter a wide range of materials, from fine particles to large solids. Plate and frame filter presses are easy to operate and can be quickly and easily cleaned, which makes them ideal for use in applications where frequent cleaning is required. They are also relatively inexpensive compared to other types of filtration equipment, making them a cost-effective solution for many applications.

Question 3: What are some common features of plate and frame filter presses manufactured by leading manufacturers?

Leading manufacturers of plate and frame filter presses offer a range of features designed to improve performance and ease of use. These features may include automatic cake discharge systems, which can improve efficiency by reducing the need for manual cleaning. They may also include advanced control systems, plate and frame filter presses manufacturers which can monitor and adjust the filtration process in real-time to ensure optimal performance. Some manufacturers may also offer customized solutions, such as specialized filter media or frame materials, to meet the specific needs of their customers. Many leading manufacturers also provide comprehensive after-sales support, including maintenance and repair services.

Some common features of plate and frame filter presses manufactured by leading manufacturers include:

Automatic cake discharge systems: These systems allow for efficient removal of the filtered solids, reducing the need for manual cleaning and increasing overall efficiency.

Advanced control systems: These systems can monitor and adjust the filtration process in real-time to ensure optimal performance and consistent results.

Customizable design options: Leading manufacturers may offer a range of options for filter media, frame materials, and other design features to meet the specific needs of their customers.

Durable and high-quality construction: Plate and frame filter presses from leading manufacturers are typically built with high-quality materials and designed for long-lasting performance.

Comprehensive after-sales support: Many leading manufacturers provide comprehensive after-sales support, including maintenance and repair services, to ensure that their customers get the most out of their equipment.

User-friendly design: Leading manufacturers may also focus on designing their equipment to be easy to operate and maintain, with features such as simple controls and easy-to-clean components.

Scalability: Some leading manufacturers offer plate and frame filter presses that can be easily scaled up or down to meet changing filtration needs, allowing customers to adjust their equipment as needed without the need for significant investment in new equipment.

Question 4: What are some factors to consider when selecting a plate and frame filter press manufacturer?

When selecting a plate and frame filter press manufacturer, there are several factors to consider. First, it is important to choose a manufacturer with a proven track record of quality and reliability. Look for a manufacturer with a strong reputation in the industry and a history of providing high-quality products and services. It is also important to consider the range of products and services offered by the manufacturer, including after-sales support and maintenance services. Finally, consider the price and overall value offered by the manufacturer, taking into account factors such as the quality of their products, their level of customer service, and their ability to meet your specific needs and requirements.