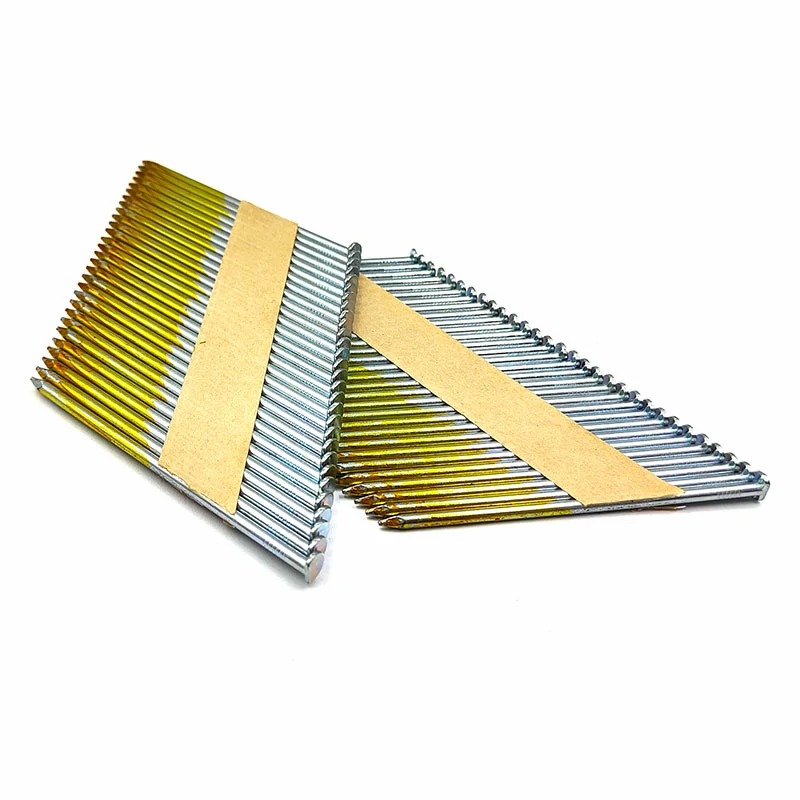

How does the cost of clipped head framing nails ?

The cost of clipped head framing nails can vary based on several factors.

Here are key considerations that influence the pricing of clipped head framing nails:

- Material Composition:

- The material used in the manufacturing of the nails plays a significant role in cost. Common materials include steel or stainless steel. The grade and quality of the material can affect the price.

- Coating Type:

- The type of coating applied to the nails for corrosion resistance impacts the cost. Common coatings include galvanized (hot-dip or electro-galvanized) and sometimes additional coatings like epoxy or polymer. Each coating has its own cost implications.

- Nail Size and Length:

- The size and length of the clipped head framing nails influence the cost. Longer and larger nails typically require more material and may be priced higher than shorter or smaller alternatives.

- Nail Gauge:

- The gauge or thickness of the nails is a factor in determining their strength and durability. Heavier gauge nails may cost more due to the increased material required.

- Brand and Manufacturer:

- Different brands and manufacturers may have varying pricing structures. Established brands with a reputation for quality may have higher prices compared to lesser-known brands.

- Quantity and Packaging:

- The quantity in which the clipped head framing nails are purchased often affects the unit cost. Bulk purchases may come with volume discounts, clipped head framing nails making the cost per nail lower. Additionally, the type of packaging (bulk boxes, collated strips, etc.) can influence the overall price.

- Special Features or Coating Options:

- Special features such as diamond points, ring shanks, or specific coating options can impact the cost. These features may enhance the performance of the nails for specific applications.

- Market Conditions:

- Market conditions, including supply and demand, can influence the cost of materials used in nail production. Fluctuations in steel prices or other raw materials can impact the overall pricing of clipped head framing nails.

- Certifications and Standards:

- Nails that meet specific certifications or standards may have higher production costs, which can contribute to a higher overall price. Compliance with industry standards for performance and safety may be reflected in the cost.

- Distribution and Retail Channels:

- The distribution and retail channels through which the clipped head framing nails are sold can impact pricing. Retailers may have their own pricing structures and policies.

- Economic Factors:

- Economic conditions, inflation, and currency fluctuations can influence the overall cost of production and, subsequently, the pricing of construction materials, including clipped head framing nails.

It’s important to consider these factors collectively when assessing the cost of clipped head framing nails. Buyers should evaluate their specific requirements, including material, size, and coating needs, to make informed decisions about the most cost-effective options for their particular construction projects.